I’ve been keeping an eye on 3d printer for sometime, about 5 years ago one turned up at work. It was a rather expensive lump, imported from the US and when by the name “makerbot”. The Buzz in the office was great and it wasn’t long before it was unpacked, powered up and printing some of the demo prints pre-installed on the SD card. After a few days, lots of WOWs, the novelty wore off and the team that were going to actually be using it took ownership and that was the last I saw of it for some time. Fun but it did highlight some points, this was a £2k printer ready made but still needed a lot of set up before prints, the speed was is issue and the big question on everyones lips was “What are they going to use it for?”

Fast forward a few years, same printer, same company, I did have a brief go at editing a toy car which was a gift for a friends son and I also knocked up mounting plate for some chrome GB lettering for a classic car. I also help a good friend print a type ring, that we stopped the print and put a real ring inside and finished the print off (Epic effort) Was I finding a use for a printer? The printer range has expanded and the cost has also fallen to levels where it no longer the luxury of big companies.

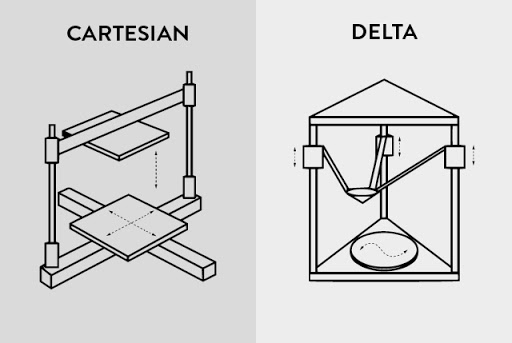

So I now officially one, why? because cost, choice and I think it will be good to find uses for myself or friends. So I have put together some info on printers that I have come across, there is also a poll at the end as I’d like to see if my lure to a Delta printer is justified. I will be buying one next month and posting on its build, along with mini review.

Ive leaning towards the Delta printer but open for suggestions

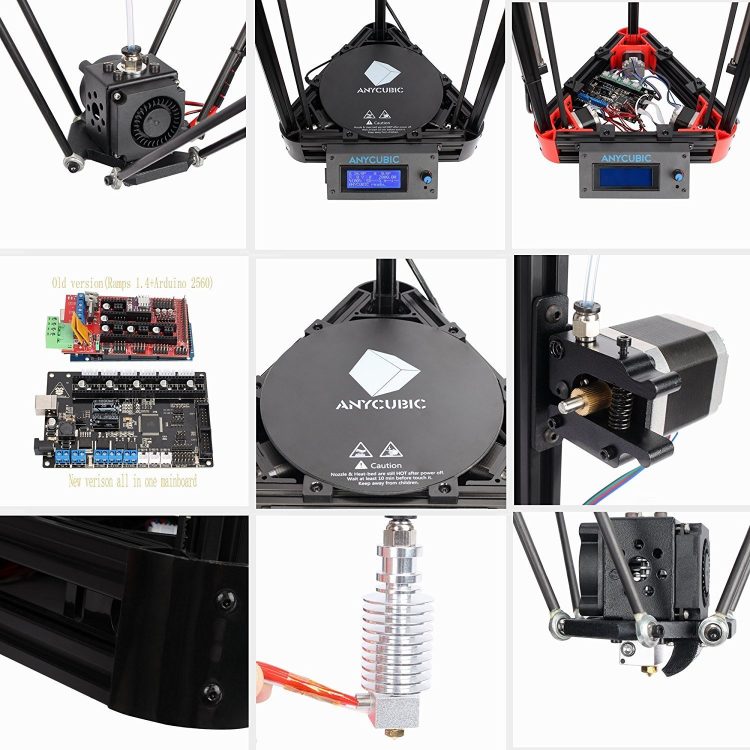

Over View Of Printer Parts (there are more but these are the main parts)

Print bed (Heated/Non-Heated)

-

-

The print bed is the surface that your objects are printed on to,Most print beds are heated in order to prevent the object from warping while it is being printed. Due to thermal contraction, the plastic will shrink slightly as it cools

-

Nozzel

-

- The most common extruding diameter is the 0.4mm (or 0.35mm) nozzle used by most current 3D printer manufactures currently available. The reason for this, quite simply is that’s it’s a great all-rounder nozzle size. This means you can print exceptional detail, and it won’t take forever. This is more often than not, for most print jobs the best nozzle size for your 3d printer.

Stepper Motors

-

-

Unlike regular DC motors, which rotate continuously when given power, stepper motors rotate in increments. This gives them precise control over their position. Most printers use NEMA 17 type motors with 200 increments (steps) per revolution.

-

Frame

-

- The frame holds everything together. Printers have frames made of sheet metal, aluminium beams, or plastic.

Motherboard

- The motherboard is the brain of the printer. It takes the commands given to it by your computer (in the form of G-Code) and orchestrates their execution. The motherboard contains a microcontroller (essentially a tiny, self contained computer) and all the circuitry needed for running the motors, reading the sensors, and talking to your computer

Stepper Drivers

- These chips are responsible for running the stepper motors. They fire the coils of the motor in sequence, causing it to move in increments

Power Supply

-

-

This takes the 240/120V AC electricity from the wall and converts it to low voltage DC power for your printer to use

-

ATX Power Supplies- These are the same power supplies used in desktop computers. They have been repurposed for use in many printers. They are very beefy and efficient, and have separate lines that provide power at a variety of voltage (12V, 5V, 3.3V).

-

What Materials Does It Print?

Filament is the material that’s consumed by the printer. It comes on a spool. Printers use two different sizes of filament, 1.75 mm and 3 mm.

PLA Polylactic Acid

ABS Acrylonitrile Butadiene Styrene

Nylon Polyamide

Wood Filaments

How Much Does A Printer Cost

This is really an open ended point, there are hundreds of printers, kits or pre-made. Brands evolved and the attack of the clones have too. I think the point should be, How much do you want to spend. A lot of video bloggers have highlighted that clones are amazing value but need lots of work to get them running where as branded pre-mades come with support and less work but as this field is still developing there is an element of trial and error with all.

There is also the experience, many gadget addict has had, will it get used for a month and then confined to the desk never to be use again. With this in mind I’m going to go cheaper and have a dabble and if needs be, upgrade over time. so on Ebay the cheapest is about £120 (might will most likely break after a while or burn your house down or both) and the all singing and dancing branded MINIFACTORY5K printers which would be over kill unless you are Tony Stark, well is Stark Plastic Industries 🙂

Im going cheap, budget for a kit is about £300 ish